Are they PNP, NPN? What are the Min/Max Voltage value for detection level?

The type of IO and voltage specification match those from the robot. You can find information about robot wrist connector IO type in TM manual.

- Digital input of IO coupling are NPN (ie Robot output is NPN)

- Digital output of IO coupling are NPN (ie Robot input is NPN)

What is the link in between Input and action of the gripper?

You can find the details of IO coupling communication in the manual.

- activate the gripper using an activation sequence

You can find detail in gripper manual:

https://assets.robotiq.com/website-assets/support_documents/document/2F-85_2F-140_TM_InstructionManual_20200211.pdf

- Trigger a pre-set action using a combination of bits. With 2 robot IO output 4 combinaison of bits are possible, therefore there are 4 possible pre-set. The 4 pre-set can be configurated via a PC using Robotiq Client Interface (RUI). RUI can be downloaded from our support page.

Look at Robotiq user interface manual for details about the pre-set configuration:

https://assets.robotiq.com/website-assets/support_documents/document/User_Interface_PDF_20191031.pdf

What is the link in between output and status of the gripper?

Output are use to provide the object detection feedback and general error status of the gripper.

bcastets

bcastets

Bobbypointe

Bobbypointe

Hi,

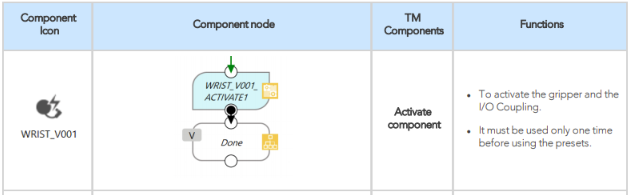

I will work with I/O Coupling On Omron TM Robots.

I can't find the precise I/O explanation about the I/O Coupling in the documentation.

Are they PNP, NPN?

What are the Min/Max Voltage value for detection level?

What is the link in between Input and action of the gripper?

What is the link in between output and status of the gripper?

Thanks